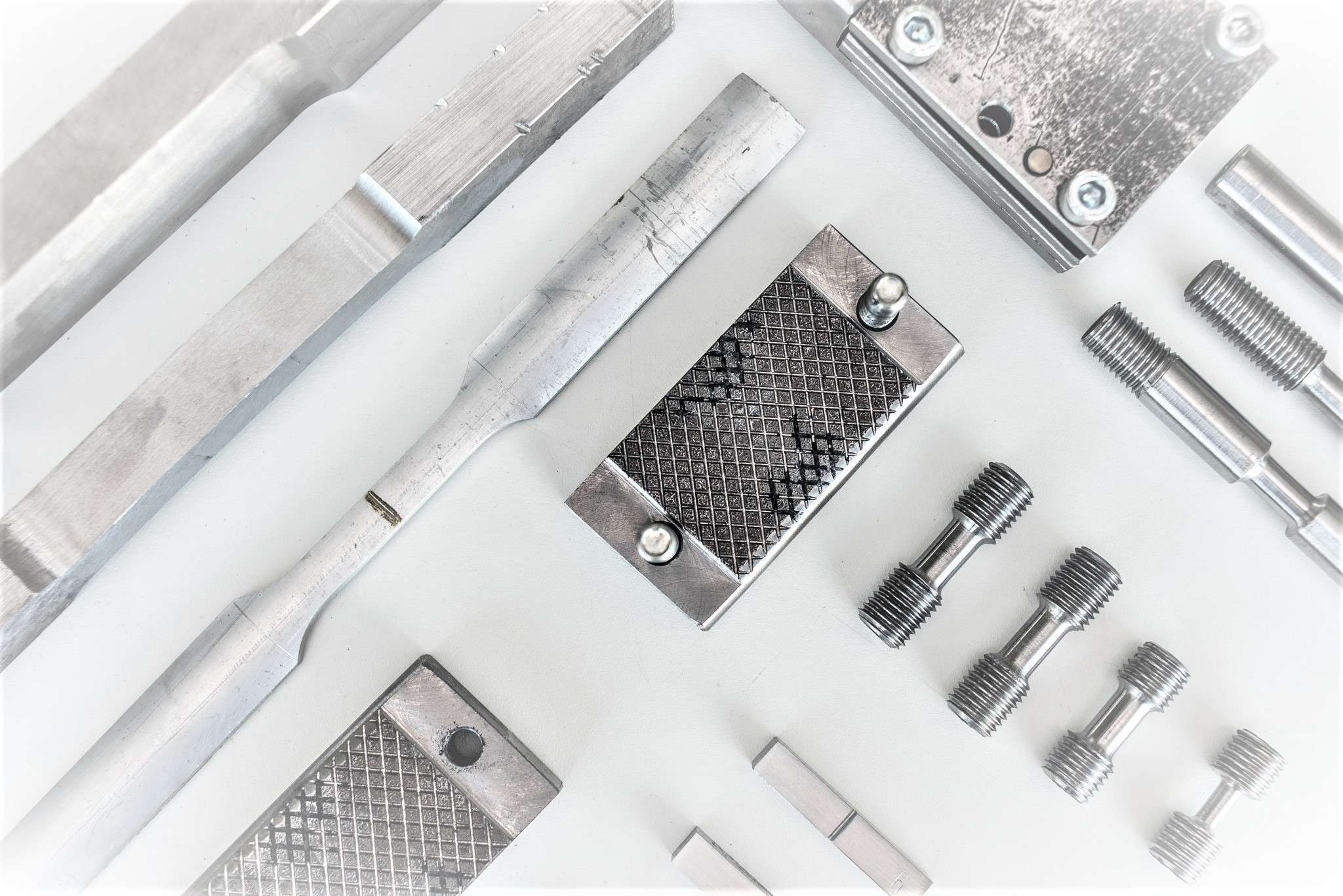

DESTRUCTIVE TESTING

Strength testing by determination of hardness, tensile strength, crack resistance and many other features are used to determine whether the material or its part is suitable for the intended use. Measured parameters are often information in the process of technology validation or design and provide information about the constraints of the material structure.

DT tests are performed by TENSLAB Sp. z o.o in close co-operation.

1. Static tensile strength test for metals and welded joints

2. Bend test of metals and welded joints

3. Fracture test

4. Hardness test of metals and welded joints

5. Impact test of metals and welded joints

6. Metallographic examination of welded joints

7. Surface roughness measurements

8. Examination of the usefulness of thermal processes, including:

- thermal cutting process according to EN 1090

- flame straightening process according to EN 1090

- geometric measurements of drilled holes according to EN 1090

9. Chemical composition analysis on mobile OES spectrometer

10. Corrosion test

TENSLAB has a machining section that allows for precise cutting and mechanical machining.