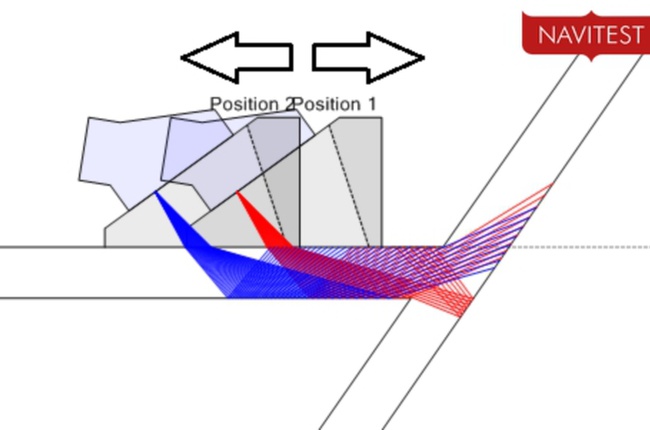

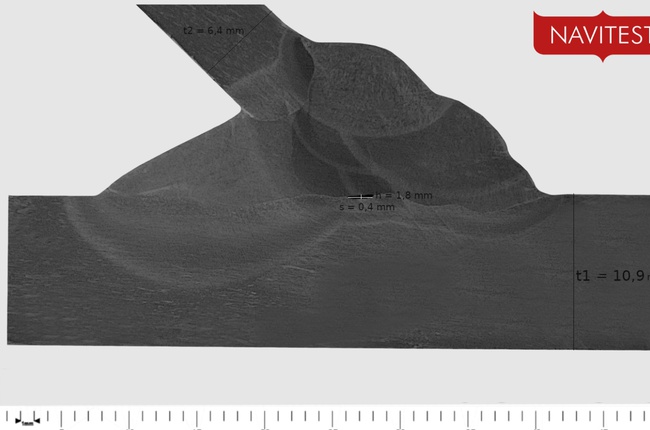

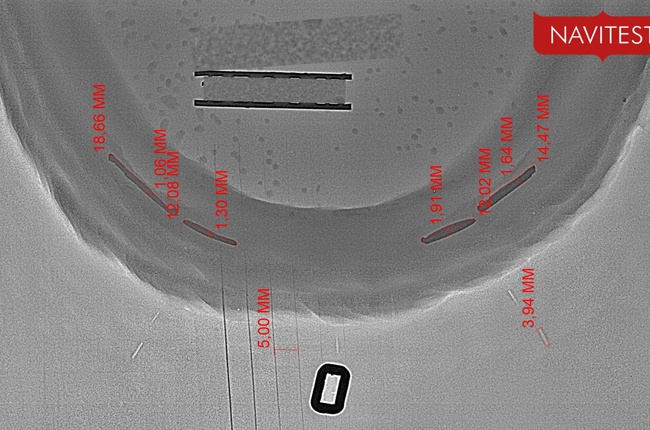

🤔 Sometimes, the idea of performing a test must first be conceived in the mind and then validated through initial trials. When the results seem reliable, they undergo detailed validation. A joint with a diameter of approximately 150 mm and a thickness close to 8 mm presents significant challenges for any volumetric method.

🛠️ At Navitest, we give special attention to such cases and work closely with customers to develop testing techniques even for the most challenging scenarios.

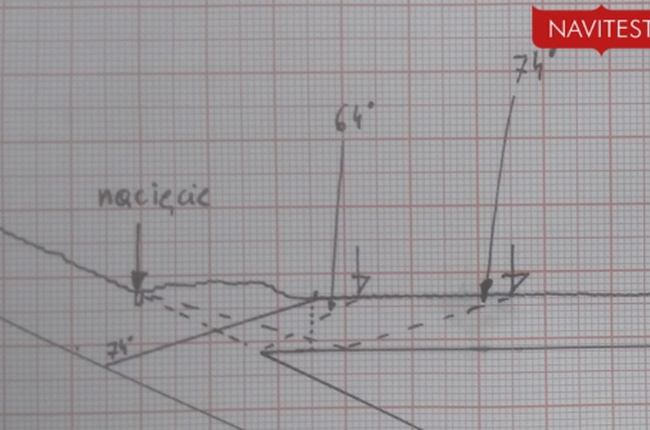

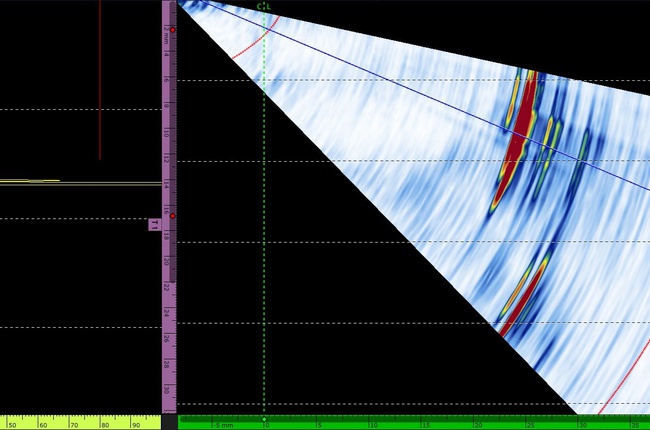

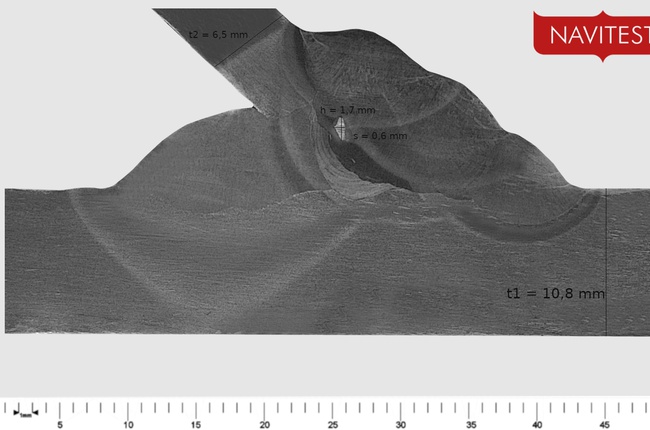

🔊 The manual application of ultrasonic techniques to such a joint seems extremely difficult. We are now completing our second project, in which we tested TKY-type tubular branch connections under highly unfavorable conditions—considering joint angle, diameter, and thickness. 🎯 Our team of specialists took on the challenge of developing a Phased Array testing technique for these demanding conditions, achieving satisfactory results. 👨🔬👩🔬 All of this is supported by digital radiography imaging.

🚫 In the absence of an alternative testing method, the structure is produced without qualitative feedback, and welders have no opportunity to learn the correct application of the welding technology being used—assuming that testing has even been conducted in the first place. 👨🏭😁

14

Mar 2025