Ultrasonic testing of welded joints of austenitic materials is very complex - in addition to the structure of the material, which can cause an increase in attenuation, there is also directionality (anisotropy). 🔄

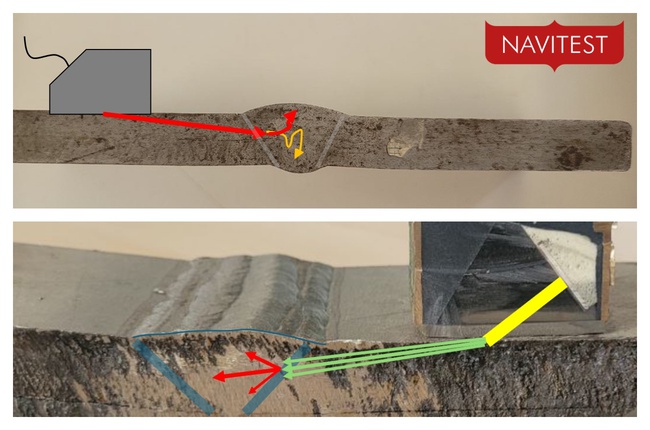

🧐 The traditionally used transverse vibration wave may not be suitable for joint volume testing. EN ISO 22825 requires verification of the test capability and specifies several combinations of parent material damping as well as the weld itself. A weld line - which has characteristically aligned dendrites - can cause not only a change in beam direction when the ultrasonic wave "breaks through" it, but also beam splitting and an increase in divergence (in the case of a transverse wave), which significantly affects its energy and the inspection capabilities themselves. ⚡

🛠️ The use of modern phased array ultrasound technology and the appropriate design of the examination not only reduces the time required to perform the examination, but it is also more accurate and reliable, and the examination itself can be performed with a record.

14

Mar 2025