CORROSION MAPPING

Corrosion mapping is a technique that maps the spatial structure of a material and identifies differences in thickness caused by corrosion. Corrosion is a deterioration of the metal material caused by chemical (or electrochemical) factors.

There are several types of corrosion:

• evenly distributed, which spreads evenly across the entire surface

• unevenly distributed (e.g. pitting, spot), characterized by the presence of local small areas with large cavities (pitting)

• intercrystalline, which extends along the grain boundaries of metal

We offer our customers ultrasound and digital radiography techniques for corrosion mapping

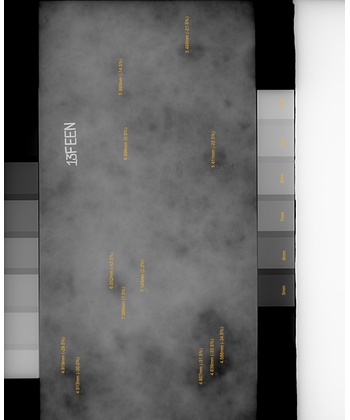

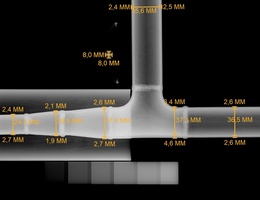

UT techniques use scanning with semiautomatic or manual scanners with encoder. Scanning involves providing adequate access, including removing the insulation, if it exists. Mapping corrosion with digital radiography does not require removal of the isolation and shutdown of the installation. This method allows for the creation of a precise corrosion map (cavity in the material) of the examined area.

Corrosion mapping is often used in the oil and gas industry for testing pipelines, pressure vessels, storage tanks and reactors. The results of corrosion mapping are characterized by high repeatability; Their advantage is the ability to track the growth of discontinuity or corrosion, both for the entire surface, as well as individual pitting, by comparing the location and the discontinuity on two scans of the same region at different times.